The product specification table

| Model | Rated Current | Rings | L(mm) | ||

| P(10A、15A) | S(2A) | ||||

| BRFG050-6P | 6 | 一 | 6 | 59.5 | |

| BRFG050-12P | 12 | 一 | 12 | 89.5 | |

| BRFG050-18P | 18 | 一 | 18 | 119.5 | |

| BRFG050-24P | 24 | — | 24 | 149.5 | |

| BRFG050-30P | 30 | 一 | 30 | 179.5 | |

| BRFG050-36P | 36 | 一 | 36 | 209.5 | |

| BRFG050-12S | 一 | 12 | 12 | 59.5 | |

| BRFG050-24S | 一 | 24 | 24 | 89.5 | |

| BRFG050-36S | 一 | 36 | 36 | 119.5 | |

| BRFG050-48S | 一 | 48 | 48 | 149.5 | |

| BRFG050-60S | 一 | 60 | 60 | 179.5 | |

| BRFG050-72S | 一 | 72 | 72 | 20.5 | |

| BRFG050-6P/12S | 6 | 12 | 18 | 89.5 | |

| BRFG050-6P/24S | 6 | 24 | 30 | 119.5 | |

| BRFG050-6P/36S | 6 | 36 | 42 | 149.5 | |

| BRFG050-6P/48S | 6 | 48 | 54 | 179.5 | |

| BRFG050-6P/60S | 6 | 60 | 66 | 209.5 | |

| BRFG050-12P/12S | 12 | 12 | 24 | 119.5 | |

| BRFG050-12P/24S | 12 | 24 | 36 | 149.5 | |

| BRFG050-12P/36S | 12 | 36 | 48 | 179.5 | |

| BRFG050-12P/48S | 12 | 48 | 60 | 209.5 | |

| BRFG050-18P/12S | 12 | 12 | 24 | 149.5 | |

| BRFG050-18P/24S | 18 | 24 | 42 | 179.5 | |

| BRFG050-18P/36S | 18 | 36 | 54 | 209.5 | |

| BRFG050-24P/12S | 24 | 12 | 36 | 179.5 | |

| BRFG050-24P/24S | 24 | 24 | 48 | 209.5 | |

| BRFG050-30P/12S | 30 | 12 | 42 | 209.5 | |

Product technical parameters

| Model | (Specification) | |

| P(10A、15A) | S(2A) | |

| Rated Voltage | 0~380VAC | 0~240VAC/VDC |

| Insulation Resistance | ≥1000MΩ/500VDC | ≥500MΩ/500VDC |

| Dielectric Strength | 1000VAC@50Hz,60S | 500VAC@50Hz,60S |

| Electrical Noise | ≤10mΩ | |

| Lsad Size | AWG14#,AWG16# | AWG26# |

| Lead Length | 500mm Standard 500mm | |

| Housing Material | Engineering Plastics or Metal online | |

| Contact Material | Preciousmetals | |

| Operating Speed | 0~500rpm | |

| Working Temperature | -20℃~+80℃ | |

| Operating Humidity | 60%RH or Higher | |

| Torque | 6环产品为0.1N.m,每增加6环加0.03N.m | |

| Protection Level | IP51 or Higher | |

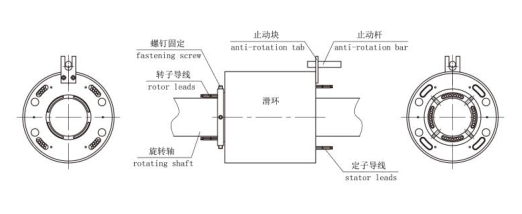

way of installation

Sincs the rotors and stators of conductile sliding bodys are very difficunlt to keep concentric during installing,It B recommended that the condnctictive sliding body be fixed to the rotating shaft nith four set screws,and the stop rod insert into scotch,Do not fix the scotch by force.

Attentions

- The slip ring should not be used for load bearing,the cables should not be stressed nor tensed.

- When installing the slip ringsf”the cables should be well protectrd.

- The slip ring should be used in dry,low dust environment,lf working environment is bad,more protection measures uld be taken.