- Home

- Products

- Wire Harness

- Page 5

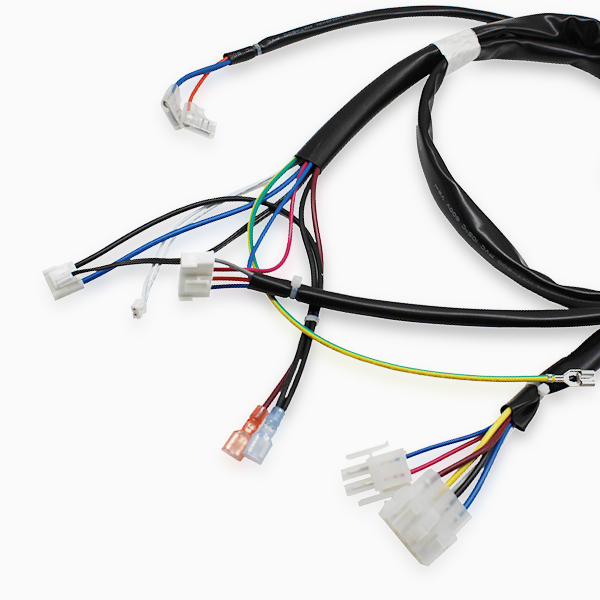

Wire Harness (cable assembly)

Wire Harness (cable assembly), is an assembly consisting of a combination of wires, cables, terminals, connectors, and other auxiliary components (such as insulating sleeves, tapes, retaining clips, etc.). In electronic equipment, automobiles, airplanes, ships, industrial machinery and other complex systems, to achieve efficient and orderly transmission of electrical energy or signals.

Wire Harness

Wire Harness is categorized in a variety of ways

Categorized by application scenarios:

1. Automotive wiring harness:

· Automotive wiring harness is specifically used for automotive electrical systems, connecting the engine, body, chassis and various types of electronic control units to ensure the normal operation of the vehicle’s functions.

2. industrial wiring harness:

· Industrial wiring harness mainly refers to the cabinet with components of some electronic wires, multi-core wires, rows of wires, etc., mostly used in industrial UPS, PLC, CP, inverters, monitoring, air conditioning, wind energy and other cabinets.

3. Medical wiring harness:

· Medical wiring harness is used in medical equipment, medical equipment supporting the connection with wiring harness products, is the line of medical electronic equipment. Its wires are usually made of high quality wires and undergo strict certification standards such as UL, VDE, CCC, JIS, etc.

4. communication wiring harness:

· Communication harnesses are used for communication equipment and security systems, such as closed-circuit monitoring, anti-theft alarm, access control attendance card, network engineering, etc.

5. Home appliance wiring harness:

· Home appliance wiring harnesses are used for the internal connection of various household appliances, such as TV sets, refrigerators, washing machines, etc.

6. Other application-specific wiring harnesses:

· Such as wind power connection harness, banking equipment harness (such as window intercom, queuing machine, LED display and other equipment connection harness), etc..

Categorized by function:

1. Drive screen harness:

· mainly used in a variety of display screen drive line, as long as it is used to display the field are involved.

2. Control harness:

· Mainly used to connect the circuit board control electrical signals, widely used in financial equipment, security equipment, new energy vehicles and medical equipment and other fields.

3.Power control wires:

· Such as switching power lines, power lines of computers, etc., used to control the power supply on and off and distribution.

4.Data transmission line:

· Used for uploading and downloading signals, such as HDMI, USB and other series of connection lines.

According to the structure of the classification:

1. Simple wiring harness: a wiring harness consisting of a small number of wires and connectors, the structure is relatively simple.

2.Branch Harness: Branch out multiple branches on the main line, each branch connects to a different device or component.

3.Cable Harness: A harness consisting of multiple cables, usually used in situations where large amounts of signals or power need to be transmitted.

4.Board Harness: A harness that is fixed to a circuit board or terminal block to realize the connection between components on the board.

5.Work Harness: Harnesses designed for specific work equipment with specific structures and functions.

According to the transmission signal type classification:

1. Analog signal harness:

· Harnesses used to transmit analog signals, such as audio cables, video cables, etc..

2. Digital signal wiring harness:

· Harnesses used to transmit digital signals, such as USB, HDMI, etc..

Classification according to technical characteristics:

1. Crimp type (Crimp): Crimp the wires and connector terminals together by crimping tool to form a reliable electrical connection.

2. Insulation Piercing Connection (IDC): Using specially designed connector terminals to pierce the insulation layer of the wire and form a connection with the conductor without stripping the insulation layer.

3. Soldering (Solder): Through the soldering process, the conductor and connector terminals are soldered together, suitable for applications requiring high reliability.

4. Winding type (Wrap): Wrap the wire around the connector terminals to form a connection, suitable for some special requirements of the occasion.

5. Injection molding into type: In addition, there are some special types of wiring harnesses, such as very fine coaxial cable series, RF coaxial connecting cable, SATA connecting cable series, flexible flat connecting cable series, row of cables series, LVDS screen cable series, HDMI Cable series, USB Cable series, etc. These wiring harnesses are designed and manufactured according to the specific application requirements and transmission media.

Classification by special requirements:

1. Waterproof wiring harness;

2. Dustproof wiring harness;

3. Wear-resistant wiring harness;

4. Low and high temperature resistant wiring harnesses;

5. Low loss wiring harness.

Our Advantages of Wire Harness

- More than 20 years of deep plowing wiring harness manufacturing, experience casting quality, trust comes from professional.

- Full chain production, wire, terminals, connectors, wiring harness core components are complete, in-depth understanding of each of your needs.

- Wire harness UL certification.

- The company has passed IATF16949, ISO9001 quality system certification, ISO14001 environmental management system certification, ISO45001 occupational health and safety management system certification.